DTF Garment Printing is a game-changing technology in the apparel industry, enabling vibrant, edge-to-edge designs on various fabrics, from cotton tees to polyester hoodies. This method uses specialized transfer films for long-lasting prints and offers designers creative freedom to produce unique, high-quality custom graphics quickly. With its versatility and environmental benefits, DTF printing is transforming fashion by appealing to customers seeking distinctive, immersive garments. Future trends predict higher resolutions, faster production, and AI/AR integration, making DTF Garment Printing a dynamic and evolving sector.

“Discover the revolutionary power of DTF garment printing, a game-changing technology transforming the textile industry. This edge-to-edge full coverage method offers unparalleled design freedom, ensuring vibrant, crisp images that pop on any fabric. From its digital precision to fast turnaround times, DTF printing delivers exceptional advantages over traditional methods. Explore its diverse applications and be among the pioneers shaping the future of custom apparel with this cutting-edge technique.”

- Understanding DTF Garment Printing Technology

- Advantages of Edge-to-Edge Full Coverage

- Applications and Future Trends in DTF Garment Printing

Understanding DTF Garment Printing Technology

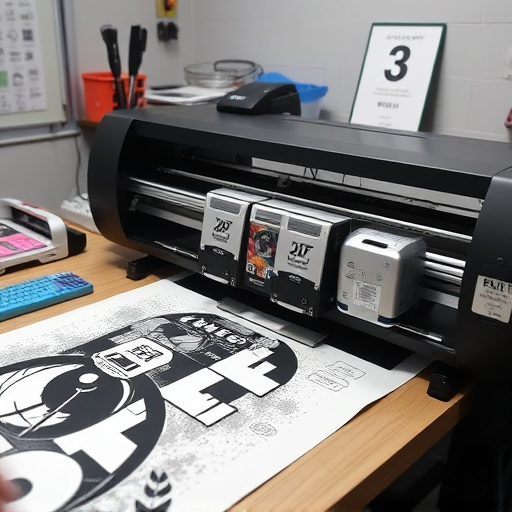

DTF Garment Printing is a cutting-edge technology that has revolutionized the way we create custom apparel and promotional products. It stands for Direct to Garment, which describes the process perfectly – ink is applied directly onto the garment’s surface, allowing for precise, vibrant, and edge-to-edge printing. This method is particularly remarkable for its full coverage capability, enabling designers and creatives to produce stunning, detailed graphics with no limitations on color or design complexity.

The heart of this technology lies in the use of DTF transfer films, which act as a conduit between the inkjet printer and the fabric. These films ensure that the ink adheres firmly to the garment, resulting in long-lasting, high-quality prints. DTF is especially favored for its versatility, making it suitable for a wide array of textiles, from cotton t-shirts to polyester hoodies, and even accessories like phone cases and bags. For those seeking unique Custom graphic tees or any other DTF applicable product, this technology offers unparalleled customization possibilities, turning ideas into tangible, eye-catching creations in no time.

Advantages of Edge-to-Edge Full Coverage

The advent of DTF (Direct-to-Garment) garment printing has revolutionized the way we approach custom apparel design. One of its most significant advantages is the capability to deliver edge-to-edge, full coverage prints. This technology allows for a seamless and comprehensive application of designs, ensuring that every inch of the fabric is utilized effectively. Unlike traditional methods that often leave empty spaces or require additional finishing touches, DTF printing provides a complete and immersive print experience.

This full coverage approach offers numerous benefits. It enhances the visual appeal of garments by creating a more dynamic and impactful design. Moreover, it allows for greater creative freedom, enabling designers to explore intricate patterns, bold colors, and complex graphics without compromise. The result is a final product that stands out in the market, catering to customers seeking unique and personalized fashion statements.

Applications and Future Trends in DTF Garment Printing

The applications of DTF Garment Printing are vast and ever-growing. This innovative technology is transforming the apparel industry by offering a diverse range of creative possibilities for designers and manufacturers. From custom t-shirts to limited-edition collaborations, DTF for Apparel allows for intricate and detailed designs that extend from edge to edge, ensuring every garment stands out in a crowd. The process is not only efficient but also environmentally friendly, as it eliminates the need for harmful chemicals often associated with traditional printing methods.

Looking ahead, future trends in DTF Garment Printing promise even more excitement. With advancements in direct to film printers, the industry is witnessing higher resolution prints and faster production times. This evolution suggests a move towards hyper-personalization, where each piece of clothing can be tailored to individual preferences. Additionally, the integration of digital technologies like AI and AR could further democratize design, enabling artists and enthusiasts from all walks of life to contribute to this dynamic landscape.

DTF garment printing has revolutionized the textile industry with its edge-to-edge full coverage capability, offering unparalleled design freedom. This technology’s advantages are clear, from creating vibrant, detailed prints on various fabrics to streamlining production processes. As we look ahead, DTF garment printing’s future seems promising, with expanding applications and trends that continue to push creative boundaries. By embracing this innovative approach, brands can elevate their product offerings and capture the attention of discerning consumers in today’s competitive market.