DTF (Direct-to-Film) garment printing revolutionizes custom apparel by directly transferring intricate designs onto film, enabling vibrant, soft, and flexible prints on various fabrics. This efficient method streamlines production, caters to both small artists and large manufacturers, and offers unparalleled versatility and quality, making it the go-to for high-resolution, long-lasting apparel with rapid turnaround. Best practices include preparing high-res digital files, using textile-specific inks, pre-treating fabrics, and utilizing tools like DTF gang sheet builders.

Discover the future of garment printing with DTF (Direct to Fabric) technology. This innovative process ensures soft, flexible print finishes on a wide range of fabrics, opening up endless possibilities for designers and manufacturers. In this article, we explore the benefits of DTF printing, from its ability to produce vibrant colors and intricate details to its suitability for various applications. Learn best practices and unlock the potential of DTF garment printing for your next project.

- Understanding DTF Garment Printing Technology

- Benefits of DTF Printing for Soft, Flexible Prints

- Best Practices and Applications for DTF Garment Printing

Understanding DTF Garment Printing Technology

DTF (Direct-to-Film) garment printing is a cutting-edge technology revolutionizing the custom apparel industry. This innovative process involves transferring print designs directly onto film, which is then used to apply intricate patterns and graphics onto clothing fabrics. Unlike traditional methods, DTF printing offers unparalleled flexibility and quality, making it a favorite among designers and businesses catering to diverse fashion needs.

With DTF transfers ready to press, the entire process becomes streamlined and efficient. The direct-to-film technique ensures vibrant, soft, and flexible print finishes, ideal for creating unique, personalized garments. This technology accommodates custom orders with ease, allowing for one-of-a-kind designs and rapid production turns around. As a result, DTF printing has become the go-to method for producing high-quality, on-trend apparel, catering to both small-scale artists and large-volume manufacturers alike.

Benefits of DTF Printing for Soft, Flexible Prints

DTF (Direct to Film) Garment Printing offers several significant advantages for achieving soft and flexible print finishes on various fabrics. This cutting-edge technology eliminates the need for traditional printing methods, such as screen printing or heat transfers. By bypassing intermediate steps, DTF printing ensures a smoother, more consistent process, resulting in superior quality prints.

One of the key benefits is its versatility; DTF transfer films can be applied to an extensive range of materials, including cotton, polyester, and even nylon, making it suitable for clothing, accessories, and promotional items. The direct application of ink onto the film allows for intricate designs with vibrant colors and fine detail, ensuring that soft, flexible garments maintain their print integrity over time. Additionally, DTF printing is efficient, faster than traditional methods, and can produce high-resolution images without the risk of smudging or fading, guaranteeing long-lasting prints on even the most delicate fabrics.

Best Practices and Applications for DTF Garment Printing

DTF Garment Printing offers a host of benefits for both printers and designers looking to create soft, flexible garments with vibrant prints. To achieve optimal results, it’s crucial to adhere to best practices when utilizing DTF technology. This includes preparing high-resolution digital files with proper color profiles and using suitable ink types designed for textile printing. Pre-treating fabrics according to the printer’s instructions ensures a smooth surface for consistent print quality.

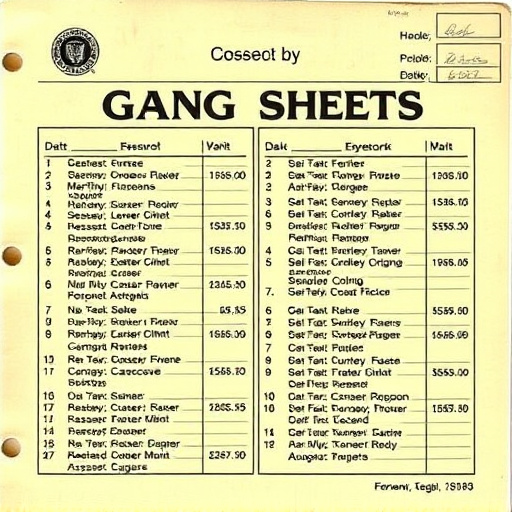

Applications of DTF Garment Printing span from custom orders to bulk production runs. Its versatility allows designers to create unique, limited-edition pieces or cater to small businesses seeking personalized clothing options. Using tools like a DTF gang sheet builder streamlines the process, enabling efficient preparation and organization of printing layouts. Remember that proper setup and adherence to dtf application instructions are key to achieving high-quality, durable print finishes on a variety of fabric types.

DTF garment printing stands out as a game-changer in the fashion industry, offering unparalleled flexibility and soft print finishes. By understanding its unique technology and best practices, businesses can tap into a diverse range of applications, from apparel to accessories. This innovative process ensures high-quality, vibrant prints that enhance the overall customer experience, making DTF garment printing a must-have for modern retailers aiming to stay ahead in an ever-evolving market.